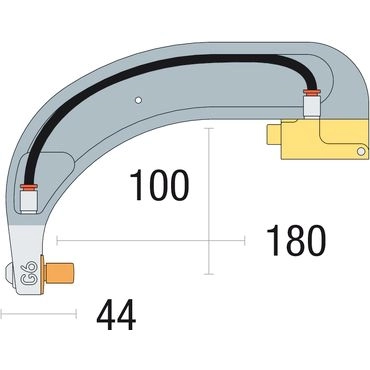

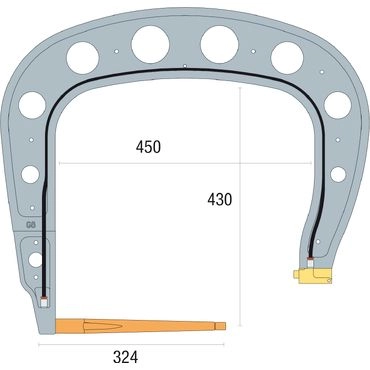

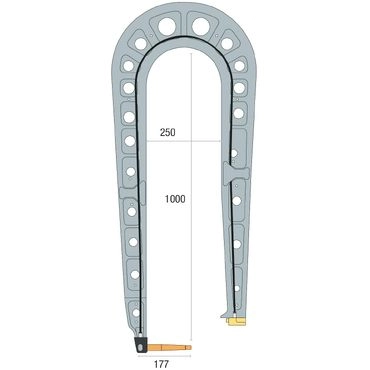

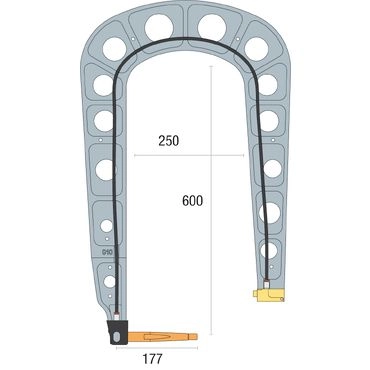

- Light weight of 11.3kg with the G1 arm

- 80 mm of automatic opening capacity (20mm at rest)

- Manual over-opening of the arm for access to difficult areas (200mm release)

- Brass clamp support and arm-base for an optimal electrical contact (effortless maintenance)

- The double action feature ensures a quick arm removal without the use of tools

- Automatic cooling connection

- Remote controlled clamp (opening, welding, adjustments validation)

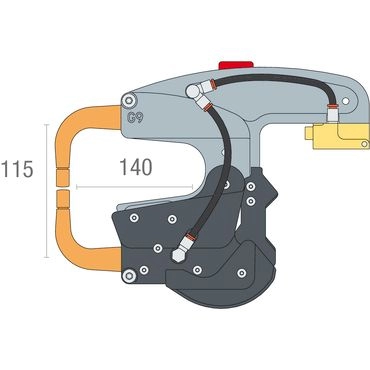

- Lockable gyroscope, ball bearing, integrated into the clamp body

- High duty cycle (18 points/min)

- Optional G9 arm suitable with auto mode

- Optional single point gun (option)

- Extends 120cm from the power source

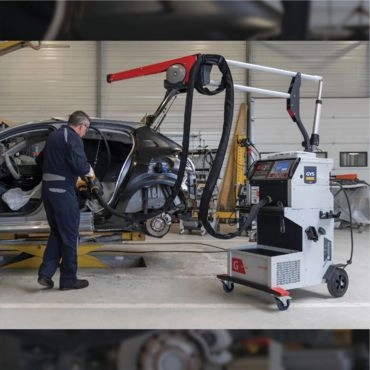

- Motorised overhanging arm to adapt the working height

- Offset balancer form the work area

- Rubber protections at the end of moving parts

- AUTO Mode: the machine automatically recognises – steel type, sheet metal thickness, panel bond presence and insulating material between HSS / VHSS / UHSS / Boron sheet metal

- Traceability: The recording feature saves the characteristics of each welding spot performed to the SD card provided

- Easily transfer saved reports onto a PC

- Welding current: 14,500 A

- Clamping force: 550daN with 8 bar air pressure

- Liquid cooling of the entire transformer, rectifier, electrodes and caps

- The new design of the G-clamp cylinder and welding algorithm maximises productivity

- User friendly navigation using the 5.7 LCD screen

- Automatic adjustment of the pressure between electrodes

- Spot count feature to determine when you need to change the caps

- Reinforced and manoeuvrable trolley with 30 litre coolant tank

- Expander on the front wheels for better stability

- Integrated 6 arm support

| Power Supply | 400V, 3phase (32A) |

| Max Welding Amp | 14,500A |

| Dimension | 71 x 90 x 200 cm |

| Weight | 100kg |

GYSPOT PTI G SPOTWELDER

Inquiry - GYSPOT Inverter Spotwelder PTI.G